Diffusion Intensity Controller

Experience the transformation of fabric through controlled saturation. Adjust the diffusion intensity to observe how patterns emerge from molecular interaction.

Pattern Generation Methods

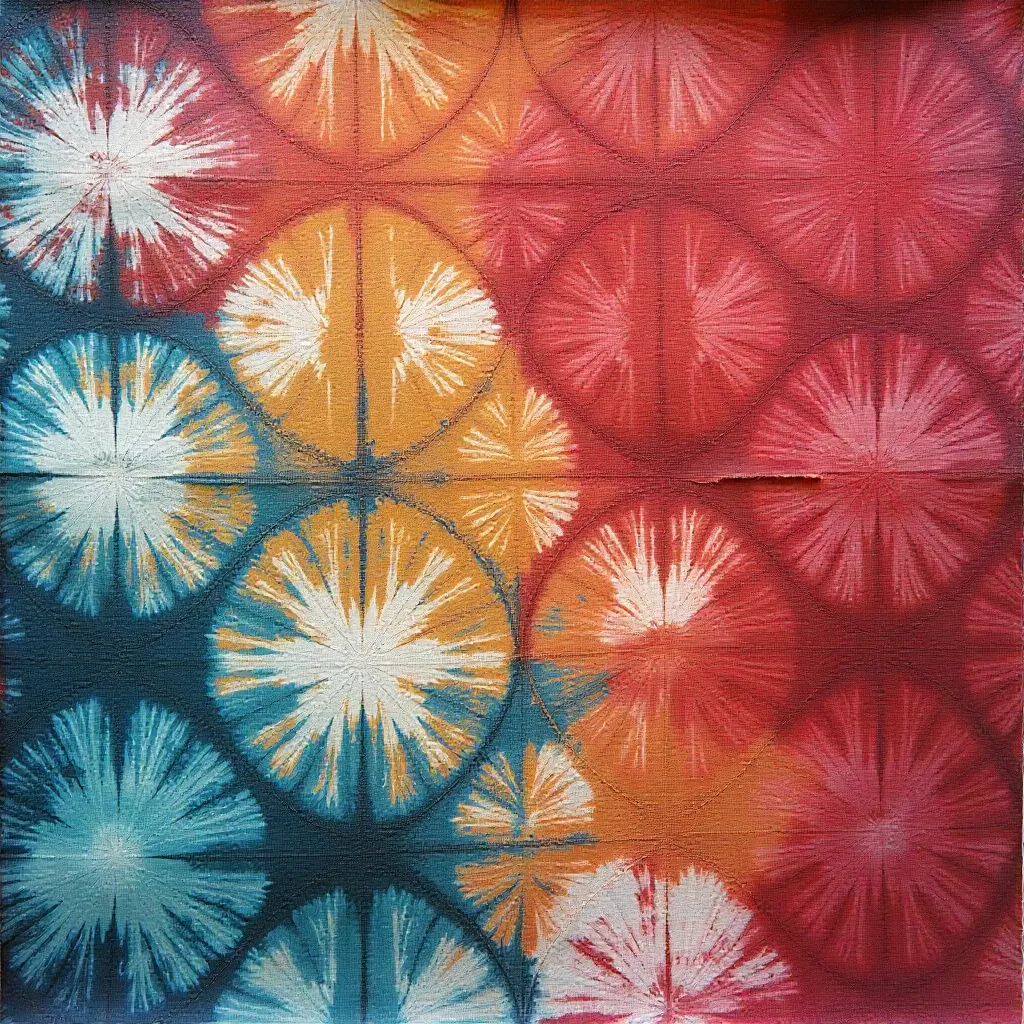

Batik Resist Application

Wax-based resist creates intricate patterns through controlled dye penetration. Each application layer builds complexity in the final composition.

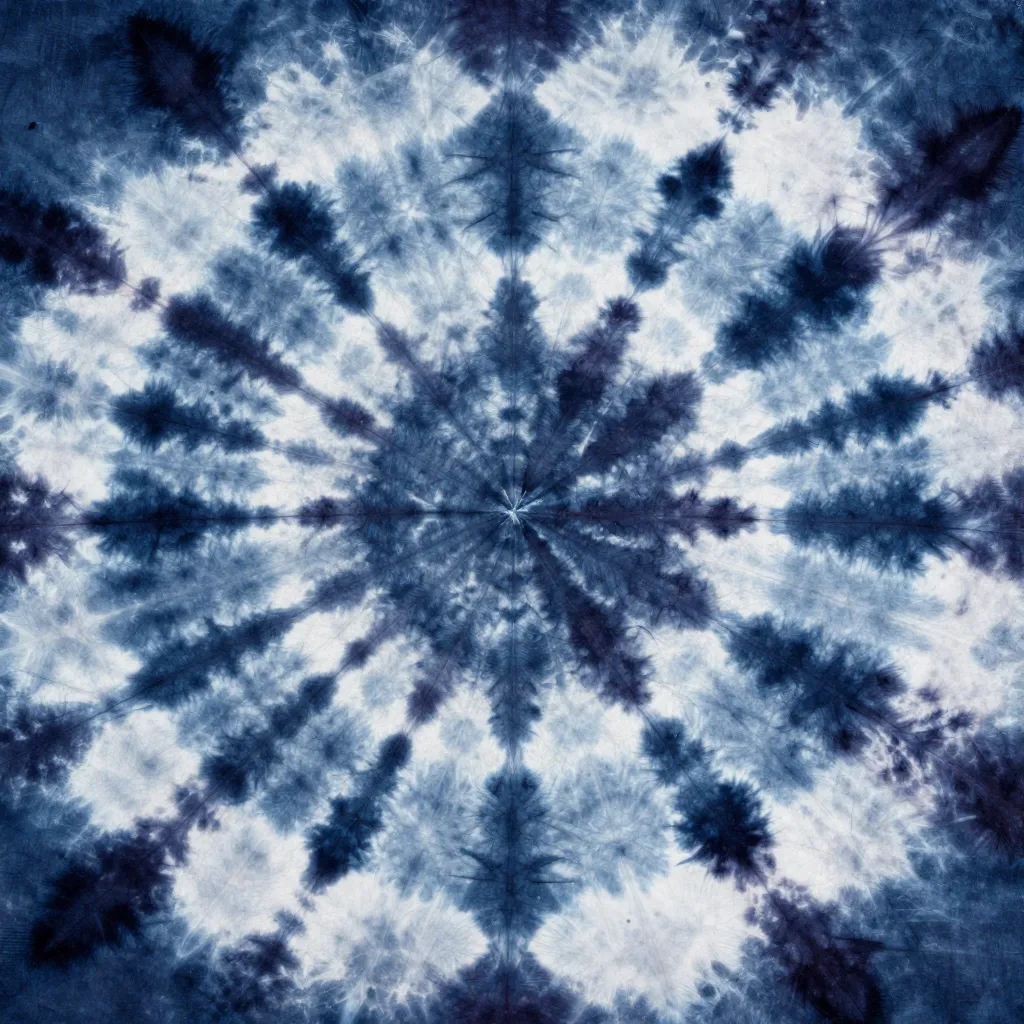

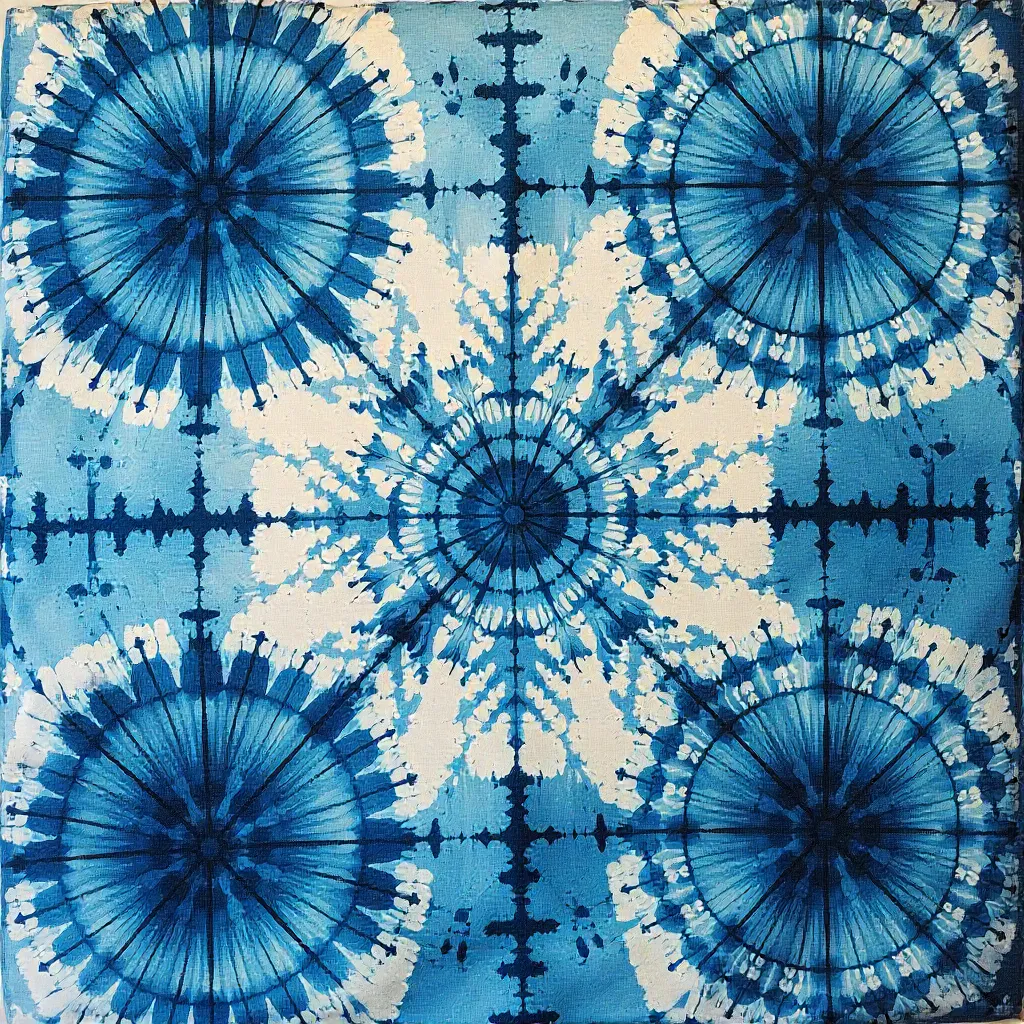

Shibori Folding Geometry

Precise fabric manipulation determines dye distribution. Mathematical folding patterns produce predictable yet organic visual outcomes.

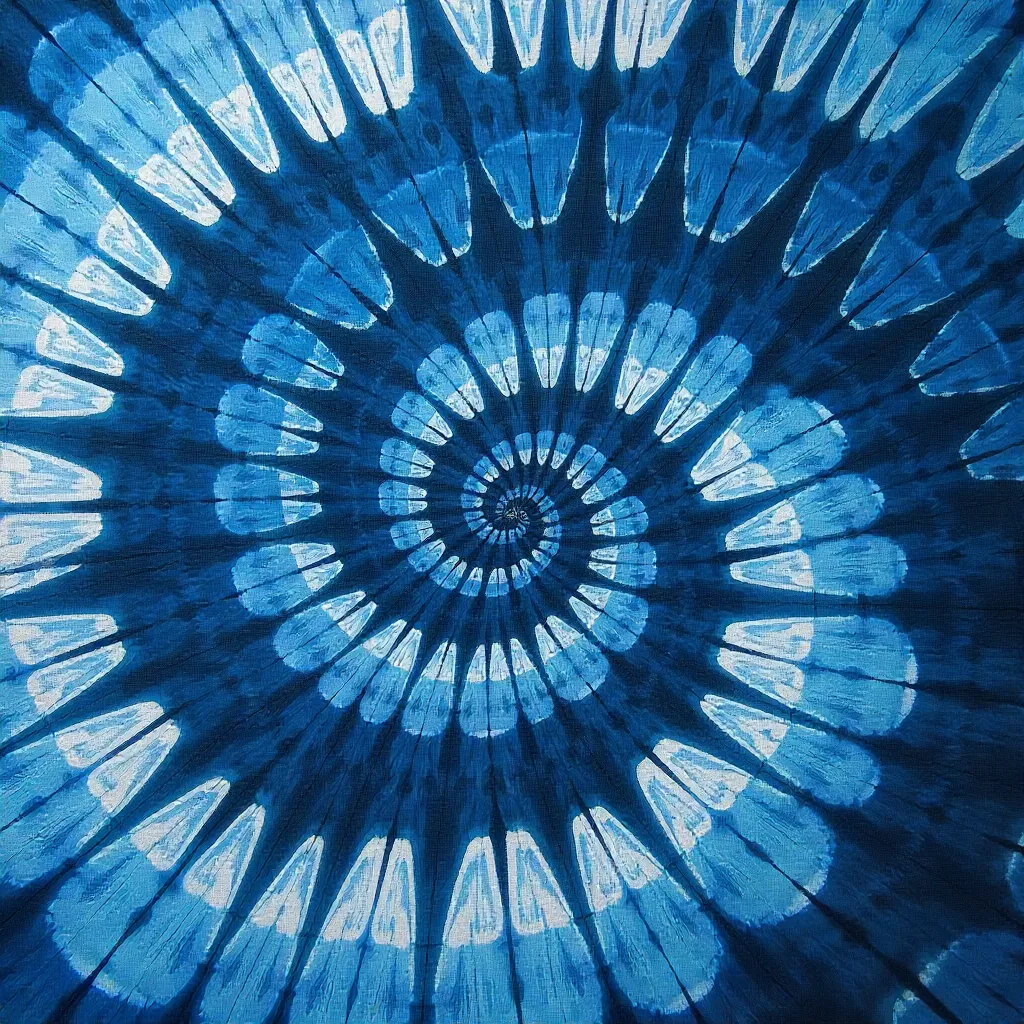

Tie-dye Spiral Dynamics

Radial binding creates centrifugal color flow. The interaction between binding tension and dye viscosity produces unique radial patterns.

Molecular Color Interaction

Fiber Absorption Rates

Different natural fibers exhibit varying molecular structures that affect dye penetration depth and color saturation levels.

Solution Concentration

The ratio of dye particles to water molecules determines final color intensity and pattern clarity in the finished textile.

Thermal Activation

Temperature regulation influences molecular movement, affecting how dye particles migrate through fabric fibers during saturation.

Technical Process Overview

Preparation Phase

Fabric pretreatment ensures optimal fiber receptivity. This includes washing, mordant application, and pH adjustment to create ideal conditions for dye bonding.

Pattern Application

Resist materials or binding techniques are applied according to the desired pattern geometry. Precision in this stage determines final visual outcome.

Saturation Process

Controlled immersion in dye solution allows molecular-level interaction. Duration and agitation patterns influence color distribution and intensity.

Fixation & Finishing

Chemical fixation ensures color permanence. Final washing removes excess dye and stabilizes the molecular bond between colorant and fiber.

Custom Color Matching

Our color theory laboratory analyzes spectral data to create precise dye formulations. Upload reference images to receive custom color recipes for your specific fiber types.

Fiber Compatibility Matrix

Silk Protein Structure

Silk's smooth surface and protein composition allow for vibrant color expression with acid-based dyes, producing rich saturation and excellent lightfastness.

Cotton Cellulose Matrix

Cotton's porous cellulose structure accepts reactive dyes effectively, creating durable patterns with good washfastness properties.

Hemp Lignin Content

Hemp's natural lignin requires specific pretreatment for optimal dye uptake, resulting in earthy tones and natural color variations.